Introduction

Peristaltic pumps are widely used in various industries for their ability to handle delicate and viscous fluids without contamination. One crucial component of a peristaltic pump system is the pipe joint, which plays a vital role in ensuring the smooth operation and longevity of the pump. In this article, we will explore the function of peristaltic pump pipe joints and discuss the importance of selecting the right materials for their construction.

Function of Peristaltic Pump Pipe Joints

Peristaltic pump pipe joints serve two primary functions within the system:

- Connection and Sealing: The pipe joint connects the different sections of tubing in a peristaltic pump system, forming a continuous flow path. It ensures a secure and leak-free connection between the pump head and the tubing, preventing fluid from escaping or air from entering the system. This function is crucial for maintaining the accuracy and efficiency of the pump’s fluid transfer.

- Compression and Occlusion: The peristaltic pump’s unique operation involves the compression and relaxation of the tubing to propel the fluid forward. The pipe joint plays a critical role in this process by providing the necessary occlusion force to compress the tubing against the pump head rollers or shoes. The joint’s design and material properties determine the effectiveness of occlusion, influencing the pump’s flow rate, accuracy, and repeatability.

Material Selection for Peristaltic Pump Pipe Joints:

Choosing the right material for peristaltic pump pipe joints is essential for ensuring optimal performance, longevity, and compatibility with the fluid being transported. Several factors should be considered when selecting materials:

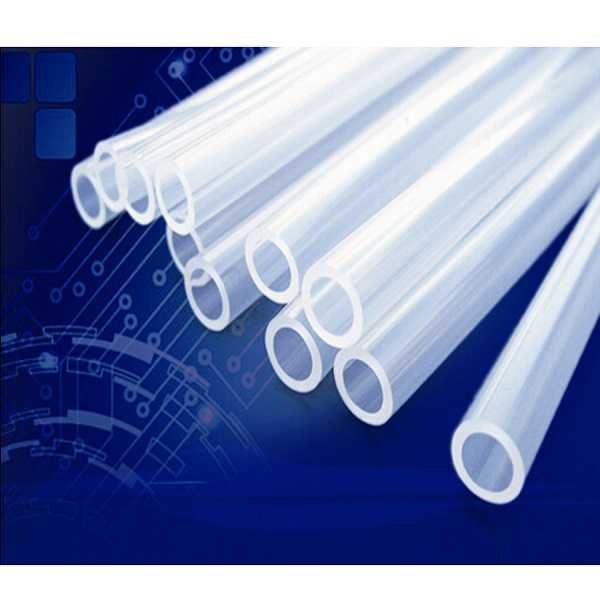

- Chemical Resistance: The pipe joint material must be resistant to the specific chemicals or fluids being handled. Different fluids may have varying levels of corrosiveness or compatibility requirements. Common materials used for peristaltic pump pipe joints include silicone, thermoplastic elastomers (TPE), and natural rubber. Each material offers different levels of chemical resistance, and the choice should be made based on the application’s requirements.

- Flexibility and Durability: Peristaltic pumps undergo repetitive compression and relaxation cycles during operation. The pipe joint material should possess excellent flexibility and elasticity to withstand these repeated motions without degradation or fatigue. Silicone and TPE are popular choices due to their high flexibility and durability.

- Sterilization Capability: In applications where sterility is crucial, such as in the pharmaceutical or food industries, the pipe joint material should be capable of withstanding various sterilization methods. Autoclaving, gamma irradiation, or chemical sterilization processes may be employed, and the material should not be adversely affected by these procedures.

- Cost Considerations: The cost of the pipe joint material should be taken into account, especially for large-scale industrial applications. While some materials may offer superior performance, their higher cost may not be justified if the application does not require their specific benefits. Balancing performance and cost is essential in material selection.

Here are some additional details about peristaltic pump pipe joints

Design Considerations

- Size and Shape: Pipe joints are available in various sizes and shapes to accommodate different tubing dimensions and connection requirements. It is essential to choose the right size and shape to ensure a secure and snug fit between the joint and the tubing.

- Compression Mechanism: The design of the pipe joint determines how effectively it can compress and occlude the tubing. Some joints utilize compression fittings, while others may have built-in rollers or shoes that apply pressure to the tubing. The choice of compression mechanism depends on factors such as the fluid viscosity, flow rate requirements, and the desired level of occlusion.

Maintenance and Replacement

- Pipe joints should be regularly inspected for any signs of wear, damage, or leakage. Depending on the application and usage, joints may need to be replaced periodically to maintain optimal performance.

- When replacing pipe joints, it is crucial to ensure compatibility with the existing tubing and the pump system. The dimensions, material compatibility, and connection type should match to maintain a reliable and leak-free connection.

Material Compatibility

- In addition to considering the chemical resistance of the pipe joint material, it is essential to assess its compatibility with the tubing material and the fluid being transported. Some materials may interact with certain fluids or tubing materials, leading to degradation, contamination, or reduced performance. Compatibility testing or consulting with the manufacturer is recommended when dealing with aggressive fluids or specialized applications.

Customization and Specialized Applications

- In certain cases, standard off-the-shelf pipe joints may not meet specific requirements. Customization options are available for peristaltic pump pipe joints, allowing for tailored solutions to suit unique applications or system configurations.

- Some specialized applications, such as high-pressure or high-temperature environments, may require pipe joints made from materials like stainless steel or reinforced polymers. These materials offer enhanced strength and resistance to extreme conditions.

Research and Development

- Manufacturers and researchers are continually exploring new materials and designs for peristaltic pump pipe joints. Advances in material science, such as the development of novel elastomers or coatings, aim to improve performance, durability, and chemical resistance.

- Ongoing research also focuses on optimizing the design of pipe joints to enhance occlusion efficiency, reduce wear and friction, and minimize the risk of contamination or leakage.

Conclusion

Peristaltic pump pipe joints play a vital role in the efficient operation of peristaltic pump systems. The joints connect and seal the tubing, ensuring a continuous flow path, while also providing the necessary compression and occlusion for fluid transfer. Selecting the appropriate material for pipe joints is crucial, considering factors such as chemical resistance, flexibility, peristaltic pump tubing connectors sterilization capabilities, and cost. By understanding the functions and material considerations, engineers and system designers can make informed decisions when selecting peristaltic pump pipe joints, leading to improved performance, reliability, and longevity of the pump system.