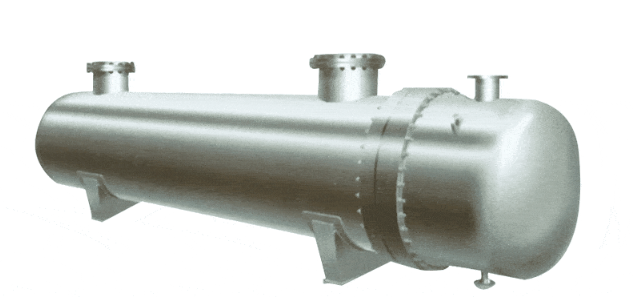

The tubular heat exchanger is a heat exchanger with simple structure, high heat exchange efficiency and strong adaptability (can be used at high temperature, low temperature, high pressure or low pressure).

The main structure of the present invention is a tube bundle composed of a plurality of tubes arranged in parallel in a cylindrical shell, with flanges at both ends, the end cover is connected with the shell by bolts, and the shell and the end cover are respectively provided with two The inlet and outlet small flanges of various media are used to facilitate the connection of corresponding pipelines.

There is a lot of knowledge about heat exchangers. Today, I will talk about the preparations before the installation of tubular heat exchangers.

1.Construction site preparation

According to the layout of the construction site, conduct an actual survey on other aspects of the site, measure and determine whether the transportation route, parking position, unloading position and the surrounding environment affect the transportation and installation of the equipment, and coordinate with relevant parties to meet the requirements of hoisting conditions.

Keep the road level and solid so that vehicles can pass smoothly and the heat exchanger can be transported to the site safely, and the installation width should meet the installation requirements.

2.Acceptance of heat exchanger equipment

Carefully check the equipment drawings, including model, quality, geometric dimensions, nozzle orientation, technical characteristics, etc.

Check the technical documents such as the factory certificate, manual, quality assurance certificate, etc., and check whether the equipment is damaged or lost (including gaskets, bolts, horns, accessories, etc.) and make inspection and acceptance records.

3.Basic acceptance

Before installation, the foundation of the heat exchanger should be carefully checked and accepted.

The foundation construction unit should submit the quality certificate, measurement records and relevant construction technical data, and the elevation line and vertical and horizontal center line should be based on the foundation, and the foundation should be cleaned up, and any defects should be dealt with.

4.Preparation for hoisting

The hoisting department should prepare all machine rigging, such as cranes, wire ropes, pulley blocks, poles, inverted chains and snap rings, etc., and check them carefully according to safety regulations. For large heat exchangers, due to its large diameter, many heating pipes, and heavy lifting weight, the lifting and binding parts should be selected at the position where the shell supports the strengthening pad.

A wooden protective casing is arranged on both sides of the casing to prevent the casing from being squeezed and deformed by the wire rope during the lifting process.

Finally, in order to carry out the installation of the shell and tube heat exchanger in an orderly manner, a construction plan should be prepared before installation, and the construction plan should include preparation instructions, project overview, construction preparation, preparation basis, technical measures and requirements, construction methods and measures, construction Machine tools, construction materials, construction staffing, construction plan progress chart, etc.