These channels have the advantage of low worth, incredible power and simplicity of interior assessment.

Activity is basic, as the edges should be full, in some other case washing is wasteful and the cake is irksome to remove. The exhausting time, the work concerned and the mileage of the material end in significant expenses.

There are a lot of clarification why a channel press couldn’t possibly at any point have a final location. Likely the main reason for it is on the grounds that a channel press is flexible to the point that it can just adjust to various positions absent a lot of change. To conclude material estimating and assuming any channel help may be expected for your slurry. Met-Chem produces new Channel Presses intended to suit your needs and spending plan. We supply a major number of Channel Press sizes and decisions required in your business and application. In the event that you wish to find out about our sand handling apparatuses, kindly reach us with the following kind.

Relating to the filtration bend of the material being separated. Is setting all things considered filtration stress or lower? Investigate channel parts for indications of disappointment, which can demonstrate a need to diminish time between administration stretches. Eye insurance and defensive garments is required. Would it be advisable for you get corrosive or scathing in your eyes or in your pores and skin, flush with water right away and look for clinical consideration, if necessary.

The channel press check may likewise give data to gauge the portion of solids to appropriately aspect a channel press unit. Before the customer resolve to buy the machine, Brilliant Victory will help the customer to decide on most appropriate life sized model for their utilization. What’s more, we will send architects to help the buyers develop the plate outline channel press framework at site. During utilizing, we will offer 24 hours telephone assistance for tackling any issue the customer could have. Nonetheless, it’s moreover essential to take note of that a bigger feed gulf is vital in enormous scope tidying applications with high transition rates (for instance, a Merrill-Crowe process).

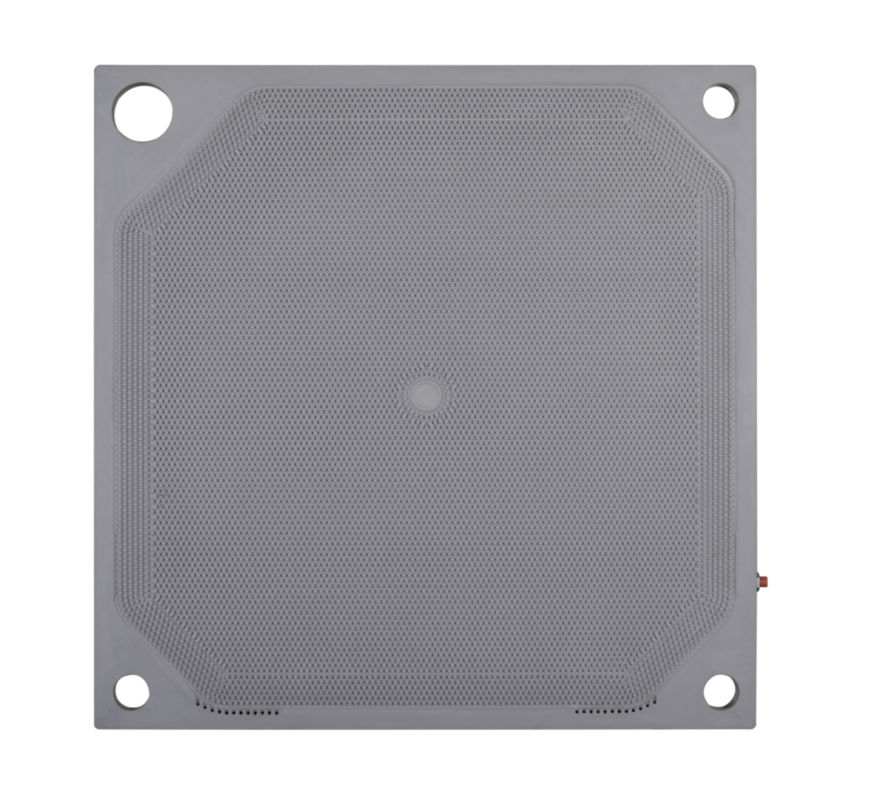

It might likewise be applied to strong fluid partition or fluid filtering processes in modern creation. Afilter pressis a product utilized in division and filtration processes, especially to isolate solids and fluids. Channel Plates As proficient channel press plates’ maker, Brilliant Victory Gathering Co., ltd can create different material channel plates used in various sorts channel press. One of the essential benefits of the recessed chamber plate configuration is the ability to take care of an enormous center opening versus a little opening toward the edge of the plate. The monster hole inside the center of the plates allows the chambers to fill speedier and extra equally, with less gamble of stopping up and incurring plate injury due to inconsistent pressure.

Later on, market calls for contemporary filtration exchange will become better and higher certificate in detachment, and fundamentally on the motivation behind material reusing, power saving, and green skill. To satisfy developing requests for higher confirmation of dewatering from challenging to-channel material, super-high pressure channels are required. Accordingly, the pattern in expanding the strain for the mechanized channel press will continue filling from here on out. These days channel presses are extensively utilized in numerous ventures, they would moreover deliver different sorts of squanders.

You ought to have gathered a sum of eleven readings toward the run’s end. We can offer you a back-up plate on the off chance that you want to downsize the limit of your press. 360 Exploration Reports is the valid inventory for acquiring the market audits that can give you the lead your business needs. Our motivation is to give the best response that matches the exact client necessities. This drives us to furnish you with altered or partnered research reports.

Met-Chem can providedelivery and establishment of your new Channel Press, bothDomestically andInternationally. Ooze division is completely mechanized in our item. By checking this case you allow us to reach you using the data presented previously.

Destructive squanders like harmful synthetic from color businesses, as appropriately as microorganism from squander stream would conceivably collect inside the waste sweets; accordingly the necessity for treating those squanders would be unique. In this way, before release squander stream into the setting, programming of post-treatment could be an essential sanitization stage. It is to prevent prosperity dangers to the local populace and the laborers which might be managing the loss as well as halting adverse consequences to our biological system.

The channel layers are then cleaned using wash fluid and the stack is re-compacted ready to start the accompanying cycle. Plate and edge channel press is a kind of industial machine utilized for strong fluid partition course of in a lot of enterprises. Broadly utilized in mining, metallurgy, synthetic business, feasts, printing and coloring, tannery, electroplating, earthenware production, drugs, coal washing, sand washing and various ventures. The channel fabrics are out there in numerous elective materials including polypropylene, polyester, cotton and other engineered supplies. The materials are delivered from both monofilament strands, multifilament filaments, or turned strands. The uniform boundary of monofilaments additionally permit textures to be delivered with reliable pore sizes.

Proceed with hopeless the palm button till the plates are all moved, wiping out the cake as you move via the plate stack.

At the point when the last plate has moved, push down the palm button when extra to deliver the plate shifter structure to its home spot, on the crosshead/chamber end of the press. When shifter is “home”, the cams will reach out up and you’re ready for another press cycle. When the result line type of the siphon arrives at a pre-set worth a clock is begun which permits the siphon to work at a chose strain for a flexible measure of time. This pre-set pressure setting is accomplished by the establishment of a pressure change in the result line of the siphon. The capability of this perform is to allow the siphon to pack more materials into the press toward the tip of the cycle, at the following strain, to all the more effectively dewater the cake.

Detach the wash framework and reinstall the ooze siphon and outlet lines. Perform and air blowdown to cleanse any leftover response from the press. Capacity tank of satisfactory ability to fill the press and take into account re-flow around 1.5 times the holding ability of the press. On the off chance that nothing from what was just mentioned supplies a response, a more exhaustive purifying interaction will be expected to break down the ensnared particulate.

The mechanical dewatering of ooze is primarily to eliminate the slender water between the muck particles. The dampness content material of the muck after unusual mechanical dewatering is frequently 65%-80%, which is looking like a mud cake. In the event that you’re amped up for learning extra about how a channel press may be modified on your particular application, contact Micronics, Inc. today. Or on the other hand we could have quite recently the legitimate typical or utilized channel press in-stock to fulfill your needs as of now. Contact Micronics, Inc. as of now and advantage from our designed filtration ability.

Data follows that can help you higher see channel material and the means it works. Nitty gritty inquiries should be coordinated to ErtelAlsop. Two plates squeezed on the whole make the whole chamber. The slurry goes through the feed eye, to the chambers where the solid piece of the slurry is saved. The Pressure driven Framework supplies the water powered liquid flow to the Pressure driven Chamber. The siphon switches instrument top notch air over completely to pressure driven strain through a proportion framework that utilizes an enormous space air cylinder at low strain to deliver an unreasonable water powered weight on a little region water powered cylinder.

Place the material contrary to the plate and spigot in a little part of the band wire or O-ring on the top to convey the material set up. Line up and caulk the askew areas first to safeguard legitimate arrangement of the texture. Appropriate the caulking on the borders, high and posterior by caulking inside the core of these extensive areas first.

One more disadvantage should be visible in changing channel fabrics. As the channel press fabricates strain, the solids develop inside the chambers until they are totally loaded with channel cake . When the chambers are full, thefill cycleis full, and the channel press is in a situation to be discharged .

To have long run collaboration relationship with all clients, Brilliant Victory Gathering constantly offer modest cost of channel press to begin the participation effectively. The beginning up and establishment choices can be found with all Met-Chem squander treatment gear. We can introduce full assistance as you get your framework up and working. We have establishment experts and specialized delegates that we are in a situation to ship off your office to guarantee the framework is running as it should dependent generally upon the designing and plan.

On the off chance that the press is working fine, report the highest level of tension inside the check between valves An and B and start your most memorable run. During the run, you really want to report the saturate course charge over the long run. This is irksome to decide from just checking out at your channel fabric. The question expects you bought your channel press from us, by which case we might have your information on report.

It ought to be noticed that water-wash is effective provided that the casings are full with channel cake. On the off chance that the solids don’t fill the casing completely, the wash water makes the cake intrude on , and afterward washing will be less productive. Thus, it is fundamental to permit the casings to transform into completely loaded up with the cake. This helps in discharging the edges as well as moreover helps in washing the cake precisely. Open the by-pass valve An absolutely and keep the channel press valve B shut.

The channel press in our research center is extensively more modest, yet the functioning standards are the very indistinguishable. The channel materials are reachable in numerous elective supplies along with polypropylene, polyester, cotton, and different engineered supplies. The fabrics are created from monofilament filaments, multifilament strands, or turned filaments. The simple surface trait of monofilament strands can assist with further developing cake send off properties. The uniform periphery of monofilaments additionally empowers materials to be delivered with steady pore sizes.

The data and tables that follow should be a spot to start for an upkeep program. Various slurries and assembling office circumstances will affect press parts in an exceptional manner. After the press is opened, the plates could be moved and the press discharged.

They at the second are known with the name Recessed Chamber Channel Press, or Layer channel Press. We are the standard channel press exporters of decision for an unnecessary number of organizations and we keep on being a strain to deal with. With our channel press plates, you could be guaranteed of pleasant quality consistently in which and a need to tweak as per the requirements of the client.

Likewise, with the recessed plate, on the off chance that you open the channel press and slide the plates, the cake drops out commonly because of it’s not held in by a 4-sided outline. The feed slurry is taken care of via the middle feed and the solids gather in the plate depression, though the separated fluid passes through the material to the waste surface. The filtration material has a rope sewn in it and it pounds into the depression in the filtration space plate and frame filter press to hold it into place. From the waste floor, the fluid streams to the corner openings the spot it goes into the release funneling after which to the cycle tanks or channel. The Plate and Casing Press is the most fundamental plan and the most seasoned kind of Channel Press. The plan is a skeleton made from metal that holds and braces the channel plates by and large to type a strain chamber.

For the most part, for the channel presses, the channel medium is the channel fabric. However, for the plate outline channel press, the channel plate is level, so aside from the channel material, it could moreover utilize the channel paper to acknowledge fabulous filtration and, surprisingly, ultra-filtration. Slurry is siphoned into the channel press by means of the feed and the solids are circulated equally in each chamber all through the press . The vast majority of the strong/fluid division is finished by the particulates building on the fabrics. From the outset, a few fines move through, yet at long last the solids start to kind a layer on the fabrics . This layer traps the fine particles and at last kinds a channel cake.

Have sufficient slurry reachable to finish the channel cycle, or secure a reinforcement plate to abbreviate the cycle. TroubleProbable CauseCorrective ActionCloudy filtrateInsufficient amount of precoat added to press.Need dose pace of 0.1lb/ft² (1225 grams/m² filtration area)Uneven conveyance of precoat 1. Certain cycles might set off fast weakening of the chamber bar. Fix or substitute of the chamber would be very costly, each in time and cost. B. In the event that previous step has no considerable exertion, decline the setting of controller. Assuming promoter keeps on cycling, the issue exists in the sponsor check valves of the essential chamber seals.

To work the shifter, begin by choosing “open” on the administration console.

At the point when the press is totally open, the administrator would push down the palm button on the shifter system. The shifter will push toward the primary plate to be moved. Once more, push down the palm button and the system will move the main plate to the slide head.

Plate and Casing Channel Pressis a noteworthy time span for contemporary dayindustrial channel pressesused in mineral handling. Channel presses from Multoteccontribute to bringing down your general cost per ton handled. Plate and Casing channel press dependent for the most part upon the instrument is surface filtration.

The channel fabrics are reused, yet the channel paper is changed after each filtration cycle. The ooze sythesis is muddled, the general thickness is little, the particles are better, and it is typically in a colloidal state, which decides its non-dewatering qualities. Consequently, beside the super high pressure vertical water driven channel press, the other channel squeezes all increment the drying system to limit back the lingering oil rate. The design comprises of an engine, an oil siphon, and a flood valve .

High filtration rate can be acquired from delivering thin cake. Be that as it may, a customary channel press is a cluster framework and the interaction must be halted to release the channel cake and reassemble the press, which is tedious. From trial work, stream charge of fluid by means of the channel medium is corresponding to the strain qualification.

The filtrate could be depleted away for safeguarded removal, or it very well may be stayed in a water tank for gone back over use. Toward the finish of filtration, the steady channel cake might be take out. The full filtration strategy is regularly guided by gadgets to give it programmed or self-loader. Brilliant Victory Gathering utilize 100% immaculateness uncooked material PP channels plates.

This licenses adaptability in the amount of sifted solids that can be delivered per group. One drawback is the way that taking care of the niche and moving through a little opening into the edge might cause stopping leaving one casing full and another void. The lopsided strain in the one edge might make the steady plate victory its waste floor and annihilate the plate. The different downside is this kind of plate is what we name non-gasketed. The fabric that looms over the plate fills in as a gasket between the plates, but regularly the material wicks fluid under tension or endlessly out spills arrangement between the plates. Normally these style of channel presses are mounted over grinding or seepage pits to accumulate the released fluid.

The center feed pipe interfaces the channel press to the item that should be sifted. The heart feed pipe get together comprises of five totally various parts. The initial segment is the lock nut which attaches on the center feed pipe and associates with the beyond the press. The line, which is the subsequent part, goes through the top of the channel and all the best way through the head plate of the channel press.

In the past advances, assuming that more than one individual is expected to lockout or label out hardware, each will put his/her own lockout or label out framework on the essentialness disconnecting gadget. At the point when an energy secluding device can’t make due with an amount of locks or labels, an amount of lockout or label out framework might be utilized. On the off chance that lockout is utilized, a solitary lock could moreover be utilized to lockout the machine/hardware with the key being situated in a lockout field or cabinet. Every representative will then utilize his/her own lock to get the case or bureau. This cycle lays out the negligible necessities for the lockout or tag out of imperativeness separating gadgets.

Plate and edge things are involved more underway purposes, as in the compound business, the spot totally various cycles require different cake thicknesses and a casing change out effectively achieves this. The cutting edge model of a Channel Press is to utilize plates that have breaks in them. At the point when these plates are pushed together, they type the cavity for solids to accumulate in. The channel press skeleton is made the same way as a plate and edge where the plates hold tight a steel outline and are clipped on the whole by a water powered chamber and siphon . Those are the main components that influence the speed of filtration.

We comprehend that each business is unique and it is our goal to guarantee that we become the No. 1 regular channel press providers. Our channel press plates have a truly unmistakable plan and could be completely modified to meet client prerequisites. The polyfilter plate licenses liquid filtration involving two types of channel sheets of different thickness in a solitary pass-through.

Specialty Coatings for Channel Presses – For very destructive conditions Met-Chem can give specialty coatings to supplant our ordinary 2-section epoxy paint. This can incorporate sand impacting of the casing and the expansion of a 2-section Vinyl Ester Covering. Channel Presses have been the essential objective of Met-Chem Assembling for a long time. One, specifically, is that for a major piece of hardware it has not many parts to it.

The fundamental air give to the machine ought to be liberated from water and oil. The presence of water or oil might make serious injury the pressure driven components. Air supply to the press ought to be at least 85 psi and the majority of 100 psi. Disengage the air supply sooner than adjusting the press.

ErtelAlsop will not be responsible for ideas given by anyone beside ErtelAlsop. [newline]Notify all impacted laborers that a lockout or label out framework will be utilized. The supported representative will know the sort and extent of force that the machine or stuff utilizes and will grasp the perils. The filtration cycle from each plate might be seen.